It is very important to install the bearing in a correctly way, but it is always easy to deviate in the actual operation, and there are endless problems. The reason is that some details are not noticed, resulting in bearing damage during installation. WXMK bearing shares several error examples of bearing installation, and correct installation methods and techniques.

Demonstration of common errors in bearing installation

The fit between shaft and bearing inner hole is too loose

Demonstration of common errors in bearing installation

The fit between shaft and bearing inner hole is too loose

Due to the fit between the shaft and the inner hole is too loose, there is sliding between the shaft and the inner hole surface. Sliding friction will cause heating and damage the bearing due to heating.

There are traces of sliding between the shaft and the surface of the inner hole

1)End face of the inner ring and the shaft shoulder are heated by friction, resulting in cracks.

When "shaft and the inner hole is too loose", the sliding friction between the inner ring and the shaft will cause high temperature. Because the contact surface between the end face of the inner ring and the shoulder is very small, the temperature will be higher. The inner ring of the bearing will be broken in use due to the continuous extension of the hot crack.

2)There is adhesion between the shaft and the inner hole surface after heating.

The high temperature caused by the sliding friction between the inner hole and the shaft surface makes the surface metal melt and produce adhesion.

Too loose fit between housing bore and bearing outer diameter

Due to the loose fit between the housing bore and the bearing outer diameter, there is sliding between their surfaces. Sliding friction will cause heating and damage the bearing.

There are traces of sliding between the housing bore and the bearing outer diameter surface.

1)Hammer strikes bearing directly

When installing the bearing with the interference fit of the inner ring (or outer ring), it is forbidden to directly knock the end face of the inner ring (or outer ring) of the bearing by hammer, so as to damage the flange easily. The sleeve shall be placed on the end face of the inner (or outer) ring and installed by striking the sleeve with a hammer.

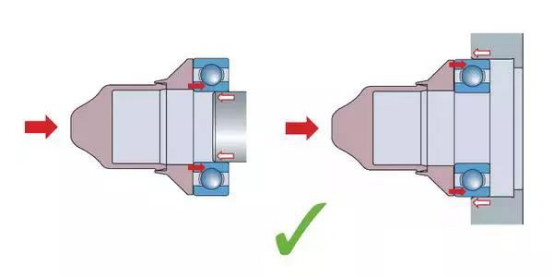

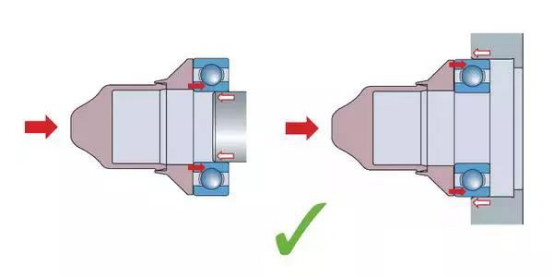

2)Transmission of installation force through rolling elements

When installing the bearing with inner race interference fit, the force can not be transmitted to the inner race through the outer race and rolling body. This will damage the bearing raceway and the surface of the rolling body, making the bearing noisy and damaged in advance during operation. The correct way is to apply the force directly on the end face of the inner ring with a sleeve.

Heating temperature is too high

Some users use acetylene spray gun to heat the bearing inner hole. When the heating temperature exceeds 727 ℃ (phase change temperature of bearing steel), the metallographic structure inside the bearing steel will change. When the bearing is cooled, the inner hole of the bearing cannot be restored to the original size, which is usually larger than the size before heating.

The surface of the bearing heated by acetylene spray gun then turns black

Correct installation way of bearing

The bearing installation shall be carried out in a dry and dust-free area as far as possible, and shall be far away from the equipment that will produce metal debris and dust. When it is necessary to install in a complex environment, pollution should be minimized.

When installing bearings, mechanical, heating or hydraulic methods shall be selected according to the type and size.

Installation of cylindrical bearing

1)Cold installation

When installing a small bearing that is not too tight, you can install the bearing in a proper position by tapping the sleeve gently with a sleeve and hammering. When striking, it should act on the bearing ring as evenly as possible to prevent the bearing from tilting or skewing.

Most bearings are installed by pressing in. If the inner and outer rings of the bearing are to be installed on the shaft and bearing seat at the same time, it must be ensured that the same pressure acts on the inner and outer rings at the same time, and the contact surface with the installation tool must be on the same plane.

2)Heating installation

In general, it is impossible to install the larger bearing without heating the bearing or bearing seat, because the larger the size is, the greater the force required for installation. The temperature difference between the bearing ring and the shaft or the bearing seat required for hot installation mainly depends on the interference and the diameter of the bearing fitting. The heating temperature of open bearing shall not exceed 120 ℃. It is not recommended to heat the bearing with seal and dust cover above 80 ℃ (ensure the temperature does not exceed the allowable temperature of seal and grease).

When heating the bearing, it should be evenly heated, and there must be no local overheating.

Bearing induction heater

Tapered bearing Installation

For bearings with tapered holes, most of the inner rings are installed by means of interference fit. The interference is determined by the axial pushing distance of the inner ring on the conical shaft diameter, the tightening sleeve or the demoulding sleeve. The larger the pushing distance on the conical mating surface, the smaller the radial internal clearance of the bearing. The interference can be determined by measuring the reduction of the clearance or the axial pushing distance.

Small and medium-sized bearings can use bearing installation tools or lock nuts to push the inner ring to a proper position on the tapered shaft diameter. In the case of tightening sleeve, use the socket nut that can be locked with hook spanner or impact spanner. To remove the sleeve, use the bearing installation tool or end plate to push it into the bearing inner hole.

Larger bearings require more force to install, so hydraulic nuts should be used. The hydraulic nut can install the tapered hole bearing on the tapered shaft diameter (Fig. 1), the tightening sleeve (Fig. 2), and the withdrawal sleeve (Fig. 3).

Way of Oil injection

The working principle of oil injection method is: under high pressure, hydraulic oil is injected into the mating surface between bearing and shaft diameter through oil hole and oil groove to form an oil film. The oil film separates the mating surfaces, which greatly reduces the friction between the mating surfaces. This method is usually used to mount the bearing directly on the tapered shaft diameter.

The necessary oil holes and grooves shall be part of the overall shaft design. This method can also be used to install the bearing on the tightening sleeve or the stripping sleeve if the tightening sleeve and the stripping sleeve have been machined with oil groove.

(Source: Maintenance of Mechanical equipment from WXMK BEARING)